Best seller Combo Vending Machine for snacks and drinks

Structure

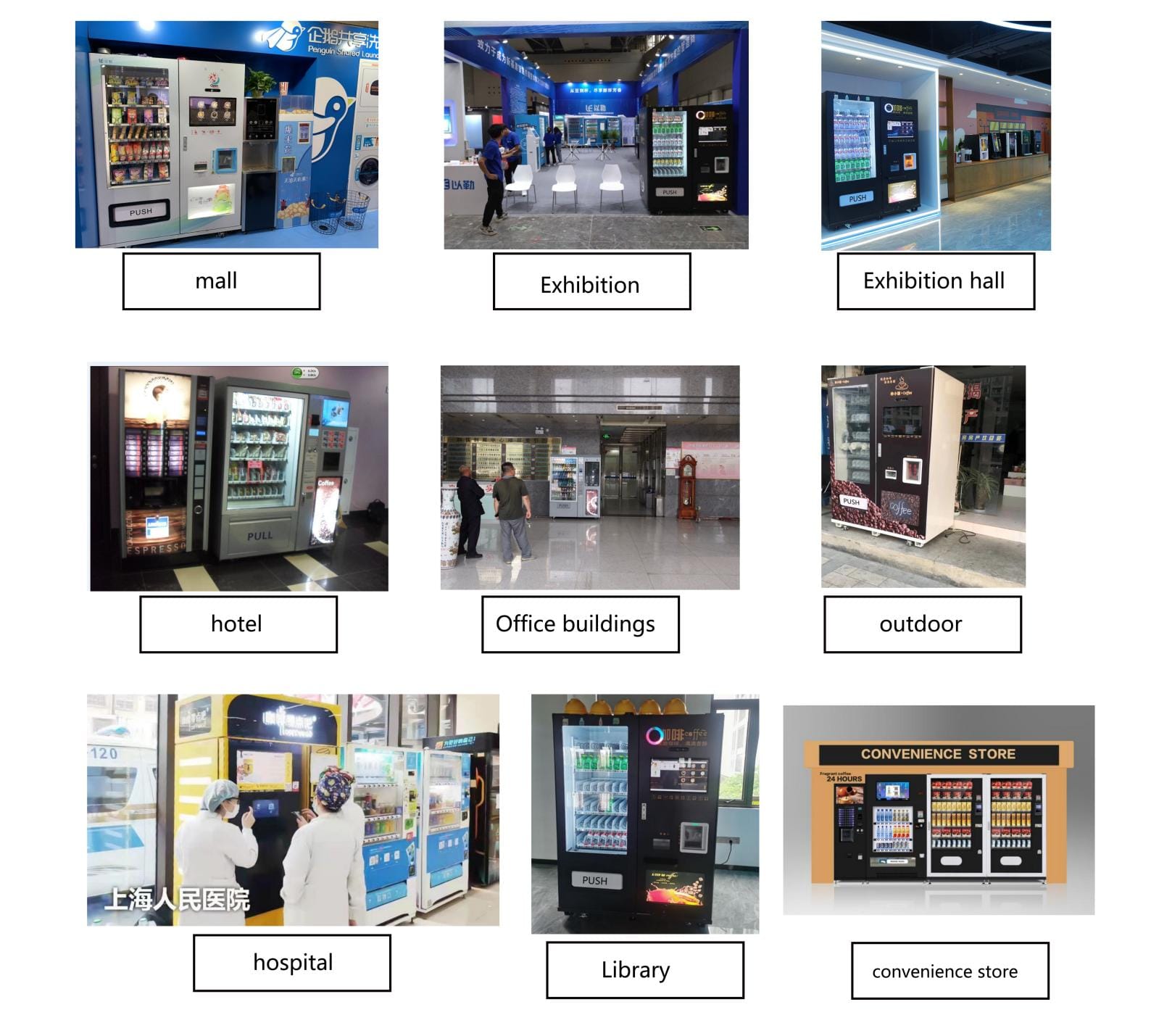

Application Cases

Hangzhou Yile Shangyun Robot Technology Co., Ltd. was established in November 2007 . It is a national high- tech enterprise who committed to the R&D, production, sales and service on vending machines, Freshly ground coffee machine, smart drinks coffee machines, table coffee machine ,combine coffee vending machine, service-oriented AI robots, automatic ice makers and new energy charging pile products while providing equipment control systems, background management system software development, as well as related after-sales services. OEM and ODM can be provided according to customer needs too.

Yile covers an area of 30 acres, with a building area of 52,000 square meters and a total investment of 139 million yuan. There are smart coffee machine assembly line workshop, smart new retail robot experimental prototype production workshop, smart new retail robot main product assembly line production workshop, sheet metal workshop, charging system assembly line workshop, testing center, technology research and development center (including smart laboratory) and multifunctional Intelligent experience exhibition hall, comprehensive warehouse, 11-story modern technology office building, etc.

Based on reliable quality and good service, Yile has obtained up to 88 important authorized patents, including 9 invention patents, 47 utility model patents, 6 software patents, 10 appearance patents. In 2013, it was rated as [Zhejiang Science and Technology Small and Medium-sized Enterprise], in 2017 it was recognized as [High-tech Enterprise] by Zhejiang High-tech Enterprise Management Agency, and as [Provincial Enterprise R&D Center] by Zhejiang Science and Technology Department in 2019. Under the support of advance management, R&D, the company has successfully passed ISO9001, ISO14001, ISO45001 quality certification. Yile products have been certified by CE, CB, CQC, RoHS, etc. and have been exported to more than 60 countries and regions all over the world . LE branded products have been widely used in domestic China and overseas high-speed railways, airports, schools,universities, hospitals, stations, shopping malls, office buildings, scenic spot, canteen, etc.

Installation Guidance

Preparation for the installation of the new machine : a pair of plastic film gloves; 2 barrels of purified water; coffee

beans, sugar, milk powder, cocoa powder, black tea powder, etc.; dry and wet wipes each; cup; cup lid; water basin

Installation process of new machine for freshly ground coffee machine.

Step 1, Place the equipment in the designated position, and the ground shall be flat;

Step 2, Adjust the feet;

Step 3 Adjust the door, and make sure open and close smoothly;

Step 4 Open the door to find the manual;

Step 5 Find the antenna and screw it to the antenna interface on the top right front of the machine;

Step 6 Put the barreled pure water into the machine bottom, and insert the pipe into the bucket (must use pure water and not mineral water) (Attention: 1. Make sure that the suction pipe is inserted into the bottom of the bucket; 2. One of the buckets needs to open the lid, cover the silicone tube, and insert the overflow pipe and the suction pipe)

Step 7 Untie the waste water induction float of the waste water bucket, and let it hang naturally in the waste water bucket;

Step 8 Open the fixing buckle of the cup drop components;

Step 9 Pull out the cup drop components;

Step 10: Fill up the Bean box

Note: 1. Take out the coffee bean house, push in the baffle, pour in the prepared coffee beans, put the bean box well, and open the baffle; Check whether the back of the bean house has been inserted into the hole.

Step 11: Fill up the other canisters

Note:

1. Remove the PE foam on the top of the canisters;

2.Rotate the nozzle upwards from left to right;

3. Gently lift the front end of one canister and pull it out;

4. Open the canister cover and put powder inside;

5. Close the cover of the canister;

6 Tilt the material box upward, align it with the opening of the blanking motor, and push it forward;

7. Put it down, aiming at the front fixing hole of the canister;

8. Clockwise or counterclockwise (To share the same mixing requires rotating in different directions) Rotate the mixing nozzle to the mixing cover, adjust the angle;

9. Repeat the same step for other canisters

Step 12 Place the dry waste bucket and waste water bucket to the designated location;

Step 13: Paper cups filling up

Note: 1. Take out the cup holder;

2. Align the paper cup hole of the cup dropper and insert it from top to bottom;

3. put the paper cups inside, don’t exceed the height of the cup holder;

4. Align the cup holder and cover the lid ;

5. All the paper cups shall be put upward and stacked one by one.

Step 14 Fill up lids

Note: 1. Open the cup lid cover 2. put the cup lids inside, and downwards, stack up one by one, not tilting.

Step 15 Bar counter installation

Note: 1. The bar is inserted into the fixing hole from the front of the door; 2. Take out the wing nut in the plastic bag together with manual and tighten it gradually;

Step 16 Put the prepared SIM Card into the PC (if you want to connect to WIFI, you can set it after powering on)

Step 17 Insert the plug-in board with ground wire;

Step 18 Power on;

Step 19 Exhaust (exhaust until water is discharged from the water outlet. If there is no water from the outlet after the first drain, you can enter the mode on the interface: press coffee test, press exhaust in coffee test);

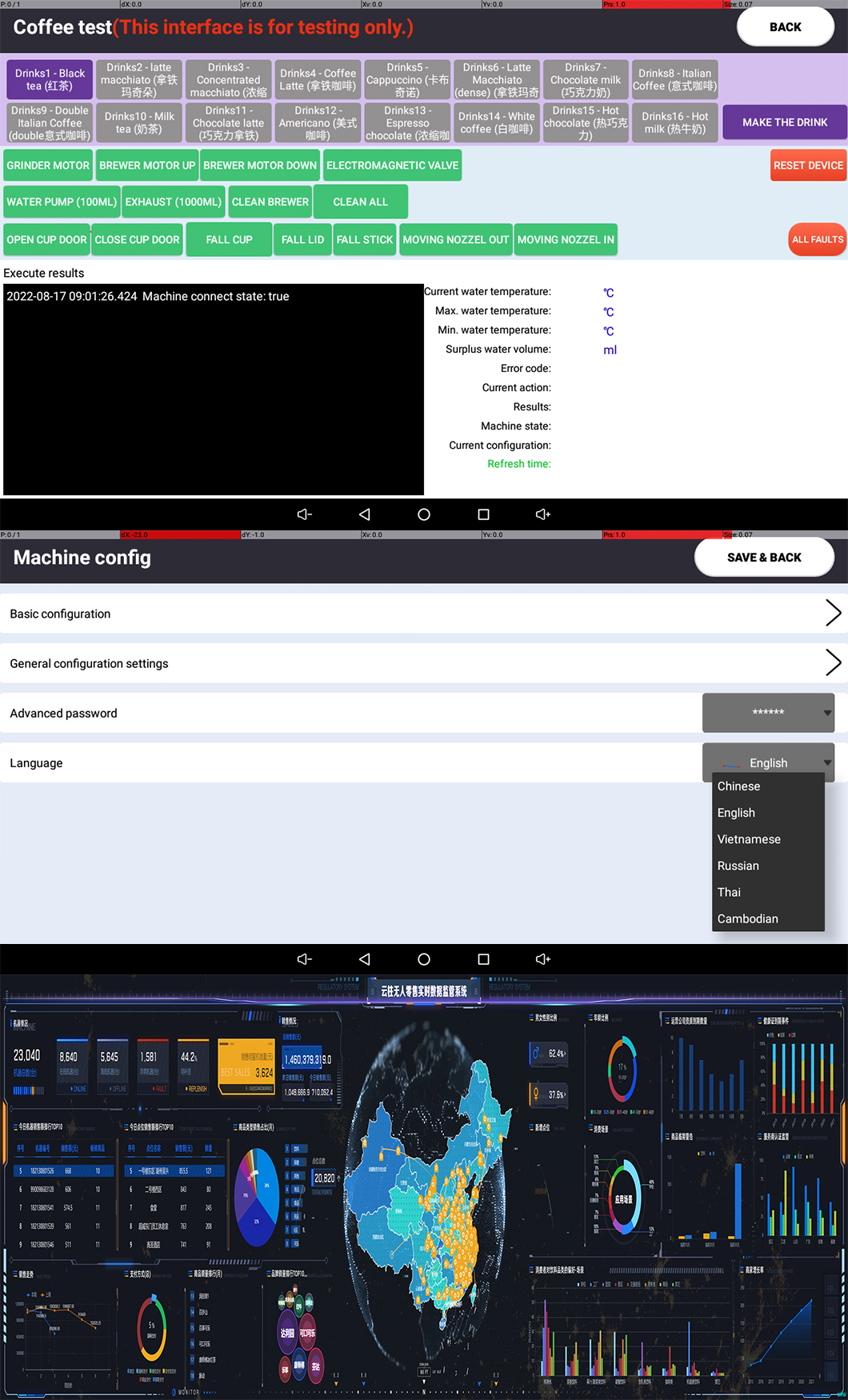

Step 20 Press the mode, and test the performance of each component on the coffee machine test page (electric door, brewing motor, cup drop, lid drop, Nouzzle moving, etc.)

Step 21: Press the mode (basic settings of coffee machine (password: 352356), click on the settings of the coffee machine canisters, and look at the powders placed in each auxiliary material box in turn (you can edit other powders here. Into different powder materials, the ratio needs to be changed)

Step 22: Adjust the price and formula ofeach powder;

Step 23 Test the taste of the drink. Note: The newly arrived equipment is allowed to stand for 24 hours before installation and testing, especially equipment with ice machine and ice water machine.